Kashan machine-made carpet is one of the most valuable and best machine-made carpets throughout the country and the Middle East. Kashan can be boldly called the center of Iranian machine-made carpet production. The city of Kashan, with several industrial towns engaged in the production and design of carpets, has made mass-produced machine-made carpets possible in Kashan. In addition to producing machine-made carpets, Kashan is also one of the main hand-made carpets hubs in Iran.

In Shadrokh Carpet, we want to introduce the Kashan machine carpet, so stay tuned.

History of Kashan machine-made carpet

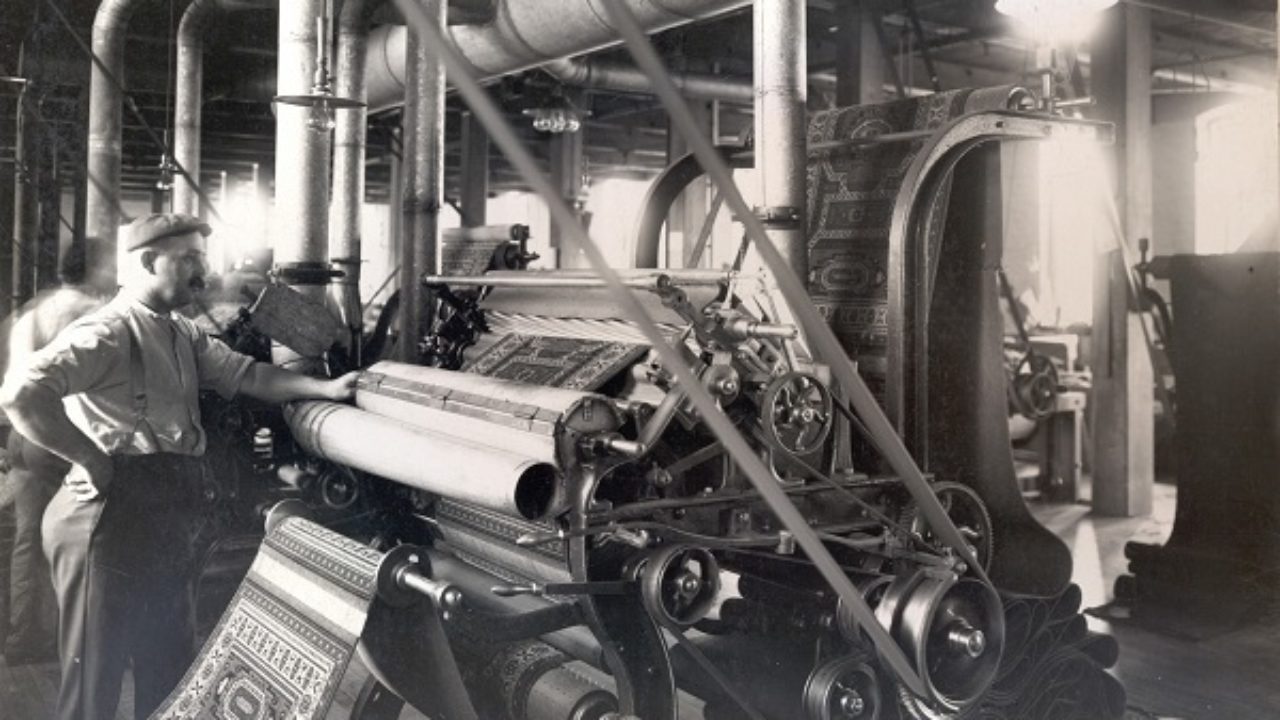

There are few official historical documents about the carpets production process in Kashan, and not be easily cited. Kashan is the first producer of the machine-made carpet industry. The first machine-made carpet was woven by Jacquard, a French machine made by Marie Jacquard, in Kashan with a low yard density. People showed a tendency to buy machine-made carpets, following the introduction of the first one to the market because it was less costly than a handmade carpet.

The process of producing machine-made carpets

We follow some production processes to produce a device or object, and carpet production is not an exemption. The first stage in the carpet production process is the production of yarn. Then, yarns are dyed upon the orders by the companies and prepared for sale and use in the industry. Machine-made carpet companies, such as Shadrokh Carpet Company, produce such yarns.

In manufacturing companies, a team produces suitable drawings with different designs and motifs. The design team allows the manufacturer to offer a variety of carpets. The machines are set to weave various carpets designs. In this part, the operators feed the machine with the required amount of yarn, given the type of the machine, and it starts weaving the carpet under the supervision.

The quality control operators check any machine-made carpet to see if some yarns are left longer than the others. Then the longer yarns are trimmed to provide the customers with a quality beautiful carpet.

Types of yarn

The machine-made carpets vary a lot, resulting in differences in prices. The main differences are the following:

- Carpets design

- Number of combs

- Density rate

- Yarn material

One of the main however less noticed differences in machine-made carpet is the type of yarn used in the carpet. In general, the carpet industry uses two types of natural or synthetic yarns. Of course, natural fibers are mostly used in hand-made carpets.

The heat-set-acrylic yarn is most widely used yarns in Kashan machine-made carpet industry.

Density and comb in machine-made carpet

The two words density and comb, which are also called longitudinal density and transverse density, respectively, include other differences among machine-made carpets. Machine-made carpet density (longitudinal density of a carpet) means the amount of knots per meter. For example, if we say that a carpet has a density of 3600, it means that this carpet has 3600 knots per meter. The comb (transverse density of a carpet) in a machine-made carpet is the number of knots in the width of the carpet per meter. For example, if a carpet has 1200 combs, it means that there are 1200 knots in each meter of this carpet.